Support our educational content for free when you buy through links on our site. Learn more

7 Robot Fighting Engineering Challenges You Must Conquer in 2026 🤖

Step into the electrifying arena where metal warriors clash, sparks fly, and engineering genius is put to the ultimate test! Robot fighting is no longer just about brute force—it’s a high-stakes battle of mechanical mastery, electrical wizardry, and software smarts. Whether you’re a seasoned builder or an aspiring combat engineer, understanding the top challenges that make or break these robotic gladiators is your secret weapon.

Did you know that over 60% of combat robot failures stem from overlooked thermal issues or power management mishaps? Or that the winning bot at the 2025 National Robotics Challenge credited its victory to software finesse rather than sheer hardware strength? In this comprehensive guide, we’ll unpack 7 critical engineering challenges—from chassis materials and weapon design to control systems and future trends—that every robot fighting enthusiast must master to dominate the arena.

Ready to build a bot that not only survives but thrives in the chaos? Keep reading to discover expert insights, real-world battle-tested tips, and the innovations shaping the future of robot combat.

Key Takeaways

- Durability and material choice are fundamental—titanium frames and hybrid armor designs offer the best balance of strength and weight.

- Power management is a silent battlefield—LiPo batteries paired with reliable ESCs require careful monitoring to avoid sudden failures.

- Weapon and mobility engineering demand precision—balancing torque, speed, and control can make or break your robot’s performance.

- Software and failsafe protocols provide a strategic edge, often outperforming brute force in high-level competitions.

- Thermal management is frequently underestimated but critical for sustained battle performance.

- Rapid prototyping and iterative testing are essential to refine designs and fix vulnerabilities before the big fight.

- Emerging trends like AI and advanced materials promise to revolutionize robot fighting engineering in the near future.

Curious about how these challenges play out in real battles and what tools the pros use? Dive into our full guide and get ready to engineer your champion!

Table of Contents

- ⚡️ Quick Tips and Facts on Robot Fighting Engineering Challenges

- 🤖 The Evolution and Engineering History of Robot Fighting

- 🔧 1. Top Mechanical Design Challenges in Combat Robots

- ⚡ 2. Electrical and Control System Engineering Hurdles

- 🛠️ 3. Software and Programming Challenges in Robot Fighting

- ⚙️ 4. Thermal Management and Heat Dissipation in Combat Robots

- 🛡️ 5. Durability and Damage Mitigation Strategies

- 🔍 Testing, Prototyping, and Iteration Techniques

- 🏆 Insights from Top Robot Fighting Teams and Engineering Experts

- 🌐 Community, Competitions, and Collaborative Engineering

- 💡 Innovative Trends and Future Engineering Challenges in Robot Fighting

- 📚 Recommended Resources and Tools for Robot Fighting Engineers

- 🎯 Conclusion: Mastering the Art and Science of Robot Fighting Engineering

- 🔗 Recommended Links for Robot Fighting Engineering Enthusiasts

- ❓ Frequently Asked Questions about Robot Fighting Engineering Challenges

- 📖 Reference Links and Further Reading

⚡️ Quick Tips and Facts on Robot Fighting Engineering Challenges

Welcome to the wild, wrench-twisting world of robot fighting engineering! At Robot Fighting™, where we live and breathe the Robot Fighting League, we’ve seen firsthand how the clash of metal titans boils down to mastering some crucial engineering challenges. Here’s a quick hit list to get you revved up:

- Durability is king: Your robot must take hits like a champ and keep fighting. Think titanium frames, hardened steel, and composite armor.

- Power matters: Lithium Polymer (LiPo) batteries are the go-to for their high energy density, but managing heat and safety is a fine art.

- Weapon design is a balancing act: Spinning blades, hammers, flippers—all need to be powerful yet reliable under extreme stress.

- Mobility wins matches: High-torque brushless motors paired with smart drive trains give you agility and control.

- Software can be a game-changer: Real-time control, failsafes, and sensor integration can outsmart brute force.

- Thermal management is often overlooked: Heat buildup can cripple your electronics mid-battle.

- Testing and iteration are your best friends: No robot is perfect out of the gate—expect to prototype, break, fix, and repeat.

Curious how these factors intertwine in the heat of battle? Stick around as we unpack every nut, bolt, and byte of robot fighting engineering! For a deeper dive into the rules shaping these challenges, check out our Robot Combat Rules and Regulations.

🤖 The Evolution and Engineering History of Robot Fighting

Robot fighting isn’t just a modern spectacle; it’s a saga of engineering innovation and relentless creativity. From the humble beginnings of remote-controlled cars with kitchen utensils strapped on, to today’s high-tech gladiators packing brushless motors and AI-assisted controls, the journey is fascinating.

- Early days (1990s): Inspired by TV shows like Robot Wars and BattleBots, builders focused on simple designs—mostly wedge-shaped bots and basic spinning weapons.

- Material evolution: Steel and aluminum gave way to titanium alloys and carbon fiber composites, dramatically improving strength-to-weight ratios.

- Powertrain advances: Transition from brushed motors to brushless DC motors revolutionized speed and torque control.

- Control systems: From basic radio controls to sophisticated microcontrollers and real-time telemetry.

- Software integration: Modern bots use embedded software for autonomous functions, sensor feedback, and battle strategy execution.

This evolution reflects the engineering community’s response to the brutal demands of robot combat: survivability, power efficiency, and precision control. For a historical perspective with a technical twist, see our Robot Design and Engineering category.

🔧 1. Top Mechanical Design Challenges in Combat Robots

Mechanical design is the backbone of any combat robot. It’s where physics meets creativity—and where many battles are won or lost before the fight even begins.

Chassis Materials and Structural Integrity

-

Material choices:

- Titanium: Offers excellent strength-to-weight ratio but is expensive and tricky to machine.

- Steel (e.g., AR500): Heavy but incredibly tough, great for armor plating.

- Aluminum alloys: Lightweight and easier to work with but less impact-resistant.

- Composites (carbon fiber, fiberglass): Lightweight and strong but can shatter under extreme impact.

-

Structural design tips:

- Use finite element analysis (FEA) software (like ANSYS or SolidWorks Simulation) to predict stress points.

- Reinforce corners and weapon mounts, which take the brunt of impacts.

- Design modular chassis for quick repairs between matches.

Pro tip: Our team swears by a hybrid chassis—titanium frame with steel armor panels—to balance weight and durability.

Weapon Systems: Types and Engineering Complexities

Combat robots typically sport one or more of these weapon types:

| Weapon Type | Engineering Challenge | Pros | Cons |

|---|---|---|---|

| Spinning Blades | High RPM, balancing, motor torque, blade durability | Devastating kinetic energy | Risk of self-damage, complex balancing |

| Hammers/Flippers | Impact force, actuator speed, energy storage | Can flip or disable opponents | Slow recharge, mechanical stress |

| Wedges/Pushers | Drive power, low profile design | Control the fight, defensive | Less offensive damage |

- Motor selection: Brushless motors like the Turnigy Aerodrive SK3 series are popular for their high torque and efficiency.

- Weapon durability: Use hardened steel or titanium for blades and impact surfaces. Consider heat treatment to prevent cracking.

- Safety: Incorporate mechanical failsafes and electronic cutoffs to prevent runaway weapons.

Mobility and Drive Train Design

-

Drive types:

- Tank treads: Great traction but complex and heavy.

- Wheels: Most common; choose between omni-wheels for agility or high-traction rubber tires for power.

- Legs: Rare and complex, but can offer unique movement.

-

Motors: High-torque brushless motors paired with planetary gearboxes provide the best balance of speed and pushing power.

-

Control: Differential steering is standard; some teams experiment with mecanum wheels for omnidirectional movement.

Our experience: A well-tuned drive train with brushless motors and a sturdy gearbox can mean the difference between being pinned or dominating the arena. For more on this, see our Robot Design and Engineering insights.

⚡ 2. Electrical and Control System Engineering Hurdles

Electrical systems are the nervous system of your robot. Without reliable power and control, even the toughest bot is a sitting duck.

Power Management and Battery Selection

-

Battery types:

- LiPo (Lithium Polymer): High energy density, lightweight, but sensitive to damage and require careful charging.

- LiFePO4: Safer and more stable but heavier and lower energy density.

-

Power distribution: Use Electronic Speed Controllers (ESCs) rated for your motor’s current draw. Overheating ESCs are a common failure point.

-

Safety: Include battery management systems (BMS) to prevent overcharge, over-discharge, and short circuits.

From our battles, we learned that battery failure is a silent killer—always double-check your wiring and monitor temperatures during matches.

Radio Control and Signal Interference Issues

- Frequency selection: Use 2.4 GHz RC systems with frequency hopping to minimize interference.

- Antenna placement: Keep antennas away from metal and electronic noise sources.

- Failsafe programming: Ensure your RC system has failsafe modes to stop the robot if signal is lost.

Sensor Integration and Autonomous Features

- Sensors: Gyroscopes, accelerometers, and proximity sensors can enhance control and situational awareness.

- Autonomy: Some teams implement partial autonomous behaviors—like self-righting or weapon activation timing—to gain an edge.

- Microcontrollers: Popular choices include Arduino, Raspberry Pi, and STM32 for custom control logic.

🛠️ 3. Software and Programming Challenges in Robot Fighting

Software is the brain behind the brawn, especially as robots become more sophisticated.

Real-time Control Algorithms

- Implement PID controllers for smooth motor speed and steering control.

- Use interrupt-driven programming to respond instantly to sensor inputs.

- Balance responsiveness with stability to avoid oscillations or sluggishness.

Failsafe and Safety Protocols

- Program automatic shutdown on loss of signal or critical sensor failure.

- Include watchdog timers to reset the system if it freezes.

- Test extensively in safe environments before competition.

At the 2025 National Robotics Challenge, the winning team credited their success to superior software control rather than mechanical complexity, proving that brains can trump brawn in robot fighting (source).

⚙️ 4. Thermal Management and Heat Dissipation in Combat Robots

Heat is the silent enemy of combat robots. Motors, ESCs, and batteries generate intense heat during battle.

- Use heat sinks and thermal pads on ESCs and motors.

- Design chassis with ventilation slots or active cooling fans.

- Monitor temperatures with onboard sensors and program throttling if needed.

We once lost a match because our ESC overheated and shut down mid-fight—lesson learned: never underestimate thermal management!

🛡️ 5. Durability and Damage Mitigation Strategies

- Modular design: Build robots with easily replaceable parts to speed up repairs.

- Shock absorption: Use rubber mounts or springs to protect sensitive electronics.

- Redundancy: Duplicate critical systems like power lines or control circuits when possible.

- Armor layering: Combine hard outer shells with energy-absorbing inner layers.

As one veteran builder said, “You don’t win by being the hardest hitter, but by being the last bot standing.”

🔍 Testing, Prototyping, and Iteration Techniques

- Rapid prototyping: Use 3D printing and CNC machining to quickly test new parts.

- Battle simulation: Conduct controlled test fights to identify weaknesses.

- Data logging: Record motor currents, temperatures, and control inputs during tests for analysis.

- Iterate fast: Fix issues and improve designs between matches—don’t wait for the next season!

Our team’s secret sauce? Fail fast, fix faster. This approach keeps us ahead in the Robot Fighting League. For detailed design tips, visit our Robot Design and Engineering section.

🏆 Insights from Top Robot Fighting Teams and Engineering Experts

- Durability over flashiness: Teams from the Combat Robot NZ group emphasize that “durability is often the difference between winning and losing” (source).

- Power balance: High-capacity LiPo batteries paired with brushless motors are the standard, but managing power distribution is a constant challenge.

- Software edge: The 2025 National Robotics Challenge winners highlighted superior software as their key advantage (source).

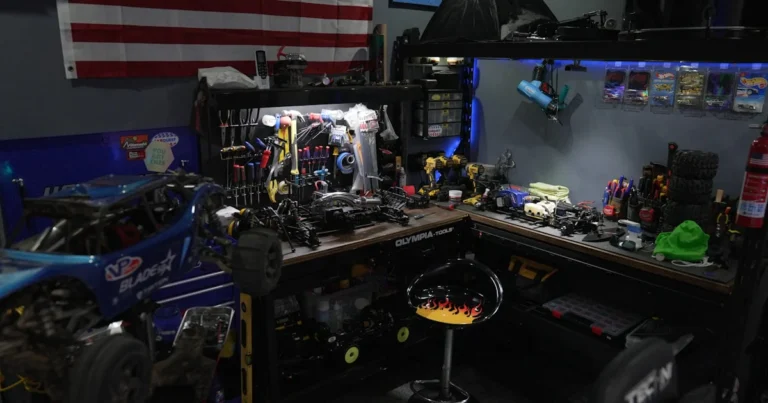

- Creative engineering: The “Most Dangerous Robot I’ve Ever Built” video (#featured-video) shows how innovative weapon design and clever engineering solutions can dominate the arena.

These insights prove that success in robot fighting is a multidimensional engineering puzzle—mechanical, electrical, and software expertise all matter.

🌐 Community, Competitions, and Collaborative Engineering

- Robot fighting thrives on community knowledge-sharing and fierce competition.

- Events like the Robot Fighting League and National Robotics Challenge foster innovation and teamwork.

- Educational programs such as the VEX BattleBots Summer Camp introduce young engineers to the challenges of combat robotics (source).

- Online forums and Facebook groups (e.g., Combat Robot NZ) are treasure troves of tips and troubleshooting advice.

Join the conversation and sharpen your skills by visiting our Robot Battle Events and Robot Combat Videos categories.

💡 Innovative Trends and Future Engineering Challenges in Robot Fighting

- AI and autonomy: Expect more robots with autonomous targeting and evasive maneuvers.

- Advanced materials: Graphene composites and shape-memory alloys could revolutionize armor and weapons.

- Energy storage: Solid-state batteries promise safer, higher-capacity power sources.

- Modular weapon systems: Swappable weapon modules for tactical flexibility mid-tournament.

- Sustainability: Eco-friendly materials and energy-efficient designs are gaining traction.

The future is bright—and complex! Are you ready to engineer the next generation of robot fighters?

📚 Recommended Resources and Tools for Robot Fighting Engineers

| Resource Type | Name/Brand | Description | Link |

|---|---|---|---|

| CAD Software | SolidWorks, Fusion 360 | Industry-standard 3D modeling and simulation tools | SolidWorks |

| Motors | Turnigy Aerodrive SK3 | High torque brushless motors favored by combat teams | Amazon Search |

| Batteries | Tattu LiPo Batteries | Reliable LiPo packs with high discharge rates | Amazon Search |

| Microcontrollers | Arduino, Raspberry Pi | Popular platforms for custom control and sensor integration | Arduino |

| ESCs | Castle Creations, Hobbywing | Electronic speed controllers with high current ratings | Amazon Search |

| Educational Kits | VEX Robotics Kits | Hands-on kits for learning robot building and programming | VEX Robotics Official |

👉 CHECK PRICE on:

For a beginner-friendly introduction, the VEX BattleBots Summer Camp is a fantastic place to start.

🎯 Conclusion: Mastering the Art and Science of Robot Fighting Engineering

After tearing through the nuts and bolts of robot fighting engineering challenges, one thing is crystal clear: success in the arena demands a perfect fusion of mechanical strength, electrical reliability, and software intelligence. Whether you’re wrestling with chassis materials, wrestling with power management, or coding the perfect control algorithm, every piece of the puzzle counts.

We’ve seen how durability often decides the winner, but raw power alone won’t cut it without smart engineering and clever design. The stories from top teams and competitions remind us that software finesse can outmaneuver brute force, and that thermal management and rapid iteration are non-negotiable for survival.

If you’re gearing up to build your own combat robot, remember:

- Choose materials wisely—balance weight and toughness.

- Invest in reliable power systems and robust ESCs.

- Prioritize mobility and control precision.

- Don’t neglect software and failsafes.

- Test relentlessly and learn from every hit and miss.

Ready to jump in? The engineering challenges are tough, but the thrill of seeing your creation duke it out in the arena is unbeatable. For beginners, programs like the VEX BattleBots Summer Camp offer a fantastic launchpad into this electrifying world.

🔗 Recommended Links for Robot Fighting Engineering Enthusiasts

👉 CHECK PRICE on:

- Turnigy Aerodrive SK3 Brushless Motors:

Amazon - Tattu LiPo Batteries:

Amazon - Castle Creations Electronic Speed Controllers:

Amazon - VEX Robotics Kits (Official):

VEX Robotics Official Website

Recommended Books:

- BattleBots: The Official Guide to the World’s Greatest Robot Combat Competition by BattleBots Team — Amazon

- Robot Builder’s Bonanza by Gordon McComb — Amazon

- Make: Combat Robots by Mark E. Rosheim — Amazon

❓ Frequently Asked Questions about Robot Fighting Engineering Challenges

What are the main engineering challenges in designing combat robots?

Designing combat robots involves juggling mechanical durability, power management, weapon reliability, mobility, and control systems. Each subsystem must withstand extreme physical stress while performing optimally. Balancing weight constraints with armor and weapon power is a constant challenge, alongside integrating electronics that can survive impacts and heat.

How do engineers improve robot durability for fighting competitions?

Engineers use high-strength materials like titanium and hardened steel, design modular components for quick repairs, and incorporate shock-absorbing mounts to protect sensitive electronics. Armor layering and redundant systems also help mitigate damage. Rigorous testing and iteration identify weak points before battle.

What materials are best for building robot fighting armor?

Common armor materials include:

- AR500 steel: Known for its abrasion resistance and toughness.

- Titanium alloys: Lightweight with excellent strength but costly.

- Ultra-high-molecular-weight polyethylene (UHMW): Lightweight and impact-absorbing, often used as a backing layer.

- Carbon fiber composites: Strong and light but can be brittle under sharp impacts.

The choice depends on weight limits, expected weapon types, and budget.

How do power supply limitations affect robot fighting performance?

Power supply limits dictate how long and how aggressively a robot can operate. Insufficient battery capacity or poor power distribution can cause motor stalls, weapon failures, or sudden shutdowns. Engineers must select batteries with high discharge rates (like LiPo packs), implement efficient ESCs, and monitor thermal loads to avoid power-related failures.

What role does AI play in robot fighting engineering?

AI is emerging as a strategic advantage in robot fighting. It enables autonomous targeting, evasive maneuvers, and real-time decision-making. While fully autonomous combat robots are rare, many teams integrate AI-assisted features like self-righting, weapon timing, and sensor-based navigation to enhance performance.

How do engineers optimize robot mobility for battle arenas?

Mobility optimization involves selecting the right drive system (wheels, tracks, or legs), pairing motors with appropriate gearboxes, and programming precise control algorithms. Engineers focus on traction, acceleration, turning radius, and stability to outmaneuver opponents. Differential steering and omnidirectional wheels are popular choices.

What safety measures are essential in robot fighting engineering?

Safety is paramount. Essential measures include:

- Failsafe programming to stop the robot if control signals are lost.

- Battery management systems to prevent fires or explosions.

- Mechanical interlocks to disable weapons during maintenance.

- Proper insulation and wiring to avoid shorts.

- Compliance with competition safety rules, detailed in Robot Combat Rules and Regulations.

📖 Reference Links and Further Reading

- Combat Robot NZ Facebook Group: Engineering Challenges Discussion

- Trine University 2025 National Robotics Challenge Report: Trine.edu

- VEX BattleBots Summer Camp Overview: Atlanta Club SciKidz

- Turnigy Aerodrive SK3 Motors: Turnigy Official

- Tattu LiPo Batteries: Gens Ace Official

- Castle Creations ESCs: Castle Creations Official

- VEX Robotics Official Website: VEX Robotics

- Robot Fighting League Home: Robot Fighting™

Ready to engineer your own champion? Dive into our Robot Design and Engineering articles and join the Robot Fighting League today! 🚀